Product Request Form

Overview:

Raagen Servo-hydraulic systems are the workhorse of any laboratory. They can perform a wide variety of low and high cycle fatigue, crack propagation, fracture toughness and other dynamic tests. Each system can be easily configured with appropriate sized servo valve, manifold and hydraulic power unit to suit the particular application. All of our systems are equipped with advanced features of the “DOLI” (German) digital controller, Console Software and unique fatigue-rated load cells. Test&Motion™ Dynpack dynamic testing software provides the backbone for running many dynamic tests. Other application specific software module allows different standardized tests to be run. These dynamic systems are ideal for running a variety of static tensile, compression, flexure, peel, tear and friction tests when they combined with Test&Motion™ and appropriate accessories.

Features of DTM Series Servo Hydraulic Dynamic Test Machines:

• Closed Loope Controlled System

• Equipped with a double ended, equal area linear actuator with hydrostatic bearings for low friction static and dynamic performance, allows high side-loads and emergency stop button, mounted on the machine.

• Designed for both dynamic and static testing on a variety of materials and components

• Adjustable upper crosshead with hydraulic lifts and lock fitted.

• Desktop or floor type servo hydraulic fatigue testing frame, easy set up to laboratory areas.

• Designed to be used with the Raagen Hydraulic Power Units

• Compatible with a large range of grips, fixtures, chambers, video extensometers, automatic extensometers and other accessories

• High technology fatigue rated loadcells that is class 0.5 according to ISO 7500-1.

• ±50/ ±75 / ±100 mm adjustable actuator stroke

• Ergonomic setup and easy to use.

|

Dynamic Load Capacity |

kN |

±5, ±10, ±30, ±50, ±100, ±250, ±300, ±500 |

||

|

Static Load Capacity |

kN |

±5, ±10, ±30, ±50, ±100, ±250, ±300, ±500 |

||

|

Actuator Stroke |

mm |

±50/ ±75 / ±100 |

||

|

Max Test Frequency |

Hz |

200 (depend on final configuration) |

||

|

Configuration |

|

A plate with a T-slot surface on the bottom of the machine, Actuator is located upper or lower side. |

||

|

Frame (width, depth, height) |

mm |

Depend on final configuration |

||

|

Load Cell |

|

Fatigue rated high precision load cell, class 0,5 |

||

|

Load Weighting Accuracy |

|

±0,5% |

||

|

Encoder (Position Measurement Sensor) Resolution |

µm |

1 |

||

|

Power Rating |

kw |

Depend on final configuration. |

||

|

Hydraulic Pressure Supply |

bar |

≥ 210, 250, 280 |

||

|

Electrical Supply |

|

380 V 50 Hz (CE compliant) |

||

|

Operating Environment |

|

+10 to +38°C (+50 to +100°F) with 10 to 90% |

||

|

Humidity Non-Condensing |

||||

|

Actuator Speed |

m/s |

Depend on final configuration |

||

|

Frame Weight (Dependent on Final Configuration) |

kg |

˷400 - 2000 (Depend on final configuration) |

||

|

Mechanical Interfaces |

||||

|

Frame strength: 0.033 mm/kN |

Desktop or floor type, selectable by user. |

|||

ASTM C1368 Slow Crack Growth of Ceramics in Flexure

ASTM C394 Shear Fatigue - Sandwich Core Materials

ASTM D3479 Tension-Tension Fatigue of Polymer Matrix Composite Materials

ASTM D7774 Flexural Fatigue Test Equipment for Plastics

ASTM E2207 Axial-Torsional Fatigue Thin-Walled Tubular Materials Test Equipment

ASTM E2368 Thermomechanical Fatigue Test Equipment

ASTM E2714 Creep Fatigue High Temperature Test Equipment

ASTM E466 Load Controlled Constant Amplitude Fatigue Tests of Metals

ASTM E467 Constant Force Axial Fatigue Test System Test Machines

ASTM E606 Strain-Controlled High and Low Cycle Fatigue Testing

ASTM E647 Fatigue Crack Growth Test Equipment

ASTM F1612 Cyclic Fatigue Testing Hip Arthroplasty Femoral Components

ASTM F1717 Spinal Implant Static and Fatigue Test Equipment

ASTM F1798 Static and Fatigue Properties of Interconnection Mechanisms and Subassemblies Used in Spinal Arthrodesis Implants

ASTM F1800 Fatigue Knee Joint Replacement Test Equipment

ASTM F1820 Fatigue Test Machine Modular Acetabular Device

ASTM F2118 Fatigue Testing Equipment for Acrylic Bone Cement

ASTM F2193 Fatigue Bending Surgical Fixation Spinal Skeletal Test Equipment

ASTM F382 Flexural Fatigue Bone Plate Fixation Devices Test Equipment

ISO 14801 Fatigue Dental Implants Test Equipment

ISO 15024 Interlaminar Fracture Toughness of Plastic Composites Test Machines

ISO 22675 Fatigue ankle foot device Prosthetic Test Equipment

ISO 7206 Hip Implants Tests

NASM 1312-11 Tension Fatigue Test Procedure for Aeronautical Fasteners

ASTM C1360 test, ASTM C1361 test, ASTM D7774 test, ASTM D671 test, ASTM D3479 test, ASTM D4482 test, ASTM D6873 test, ASTM D6926 test, ASTM E206 test, ASTM E2368 test, ASTM E399 test, ASTM E466 test, ASTM E488 test, ASTM E606 test, ASTM E647 test, ASTM E1190 test, ASTM E1290 test, ASTM F1160 test, ASTM F1717 test, ASTM F1800 test, ASTM F2345 test, ASTM F2706 test, ASTM E467-08 test, ASTM E1942-98 test, ASTM E2208-02 test, ASTM E2243-05 test, ASTM E3076-18 test, ASTM E1457 test, ASTM E1681 test, ASTM E2760 test, ASTM E468 test, ASTM E2207 test, ASTM E2244 test, ASTM E2245 test, ASTM E2246 test, ASTM E2714 test, ASTM E2789 test, ASTM E2948 test, ASTM E3097 test, ASTM E3098 test, ASTM E561 test, ASTM E740 test, ASTM E1221 test, ASTM E1820 test, ASTM E1921 test, ASTM E2472 test, ASTM E2818 test, ASTM E2899 test, ASTM E3039 test, ASTM E436 test, ASTM E1304 test, ASTM E1823 test, ASTM E2444 test, ASTM E739 test, ASTM E1049 test, ASTM E1922 test, ASTM C1368 test, ASTM C394 test, ASTM D7774 test, ASTM E2207 test, ASTM E2714 test, ASTM E466 test, ASTM E467 test, ASTM E606 test, ASTM E647 test, ASTM F1612 test, ASTM F1717 test, ASTM F1798 test, ASTM F1800 test, ASTM F1820 test, ASTM F2118 test, ASTM F2193 test, ASTM F382 test, ASTM D7791 test, ASTM E1012 test

ISO 14801 test, ISO 15024 test, ISO 22675 test, ISO 7206 test, ISO 1143 test, ISO 12107 test, ISO 3800 test, ISO 6157-3 test

NAS 1069 test, NASM 1312-11 test, NASM 1312-21 test

BS 3518 test, Part 2 & 3, BS EN 1992-1-1 test

GMN7152 test, GMW16704 test, GMW16705 test

JIS B1051 test

DOD-STD-1312-111 test, MIL-STD-1312-11 test

NASM 1312-11 test, NASM 1312-21 test, NAS 1069 test

SAE J 123 test

JSSG-2006 test

NASM8831 Rev.3c test

MIL-S-5000 REV. E test

NASM14181 test

NASM85604 test

MIL-A-8866 test

MIL-A-8867 test

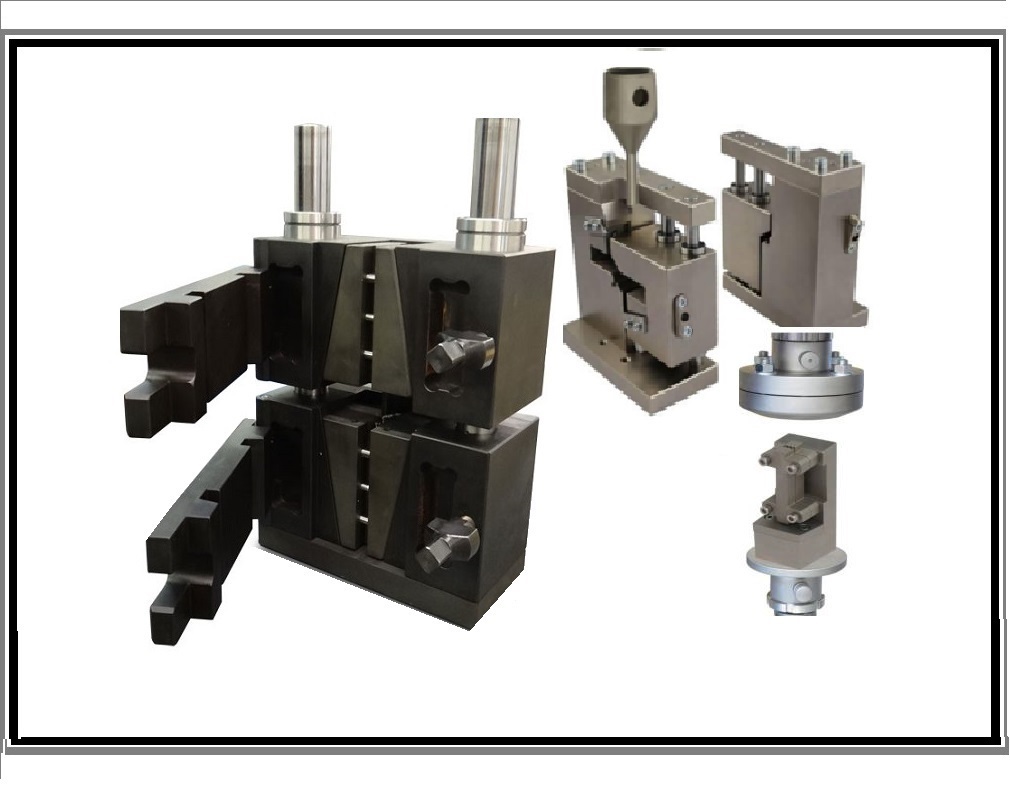

Servo Hydraulic Fatigue Test Machines Grips And Test Fixtures

Raagen has a big engineer team for designin of different test fixtures according to various test standards.This team analyse the customer's exact requirement of required tests. They offer correct fixture types and dimensions for customer.Raagen offers different kind of tensile test fixtures, compression test plates, flexural and bending test apparatus, shear test fixtures, peeling tests fixtures, eccentric rollers, chucks, puncture test fixtures, specimen cutters and cutting dies. See more...

Extensometers for Strain Measurement

Raagen offers all type of extensometers to use with electromechanical test machines to able to strain measurement of mechanical tests.

We are supplying of tensile test extensometers, clip on extensometers, compression test deflection gauges, transversal extensometers, video extensometers, laser extensometers, long travel extensometers and automatic extensometers. See more...

High Temperature Furnaces

Raagen develops, manufactures and supplies high temperature test furnaces for quality assessment in material testing under high temperature (HT).

Suitable for variety of high temperature tests, including tension, compression, bend and fatigue testing of metals, composites, ceramics and many other materials. Suitable for variety of high temperature tests, including tension, compression, bend and fatigue testing of metals, composites, ceramics and many other materials. The furnaces can using with Raagen Electromechanical Test Machines to determine material characterisation of elevated temperatures. See more...

Environmental Chambers for Universal Testing Machines

Raagen environmental test chambers provides extensive temperature testing capabilities for evaluating material properties under non-ambient testing conditions. A full range of complementary grips, pullrods and extensometers are available for using inside of environmental test cabinets.

Raagen makes high or low temperature testing is made possible by integrate an climalitical chamber to a universal testing machine.

Description

Description Techical Specifications

Techical Specifications Standards

Standards Gallery

Gallery Accesories

Accesories